Engineering Solutions for Adjusting AC Centrifugal Fan Speed to Maximize Energy Savings

Engineering Solutions for Adjusting AC Centrifugal Fan Speed to Maximize Energy Savings

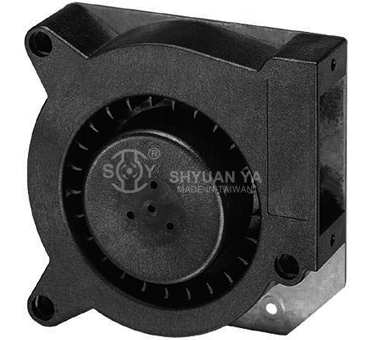

Centrifugal fans play a crucial role in a variety of industrial applications, from HVAC systems to manufacturing processes. For product development engineers, controlling the speed of AC centrifugal fans can be essential for maximizing energy efficiency, reducing costs, and ensuring optimal performance. In this comprehensive guide, we'll explore various methods for adjusting fan speed, discuss the pros and cons of each technique, and provide practical tips for effective speed regulation.

Understanding the Need for Speed Control in AC Centrifugal Fans

Why Adjusting Speed is Key for Energy Savings and Efficiency

Controlling the speed of AC centrifugal fans is crucial for both energy savings and enhancing the fan's overall performance. A fan running at a constant maximum speed may often consume more energy than necessary, especially when operating under varying load conditions. By adjusting the speed to match the operational needs, it's possible to avoid excessive power consumption while achieving the desired airflow.

Energy efficiency is directly tied to fan speed, as the power consumption of a centrifugal fan is approximately proportional to the cube of its speed (fan laws). Therefore, even a slight reduction in fan speed can result in significant energy savings. For example, reducing the speed of a fan by 20% can potentially cut energy use by up to 50%.

Relationship Between Fan Speed and Power Consumption

When an AC centrifugal fan's speed is controlled and reduced according to the application needs, power consumption decreases, and overall system efficiency improves. This relationship is governed by the "Affinity Laws," which state:

• Airflow is directly proportional to fan speed.

• Pressure developed is proportional to the square of fan speed.

• Power consumption is proportional to the cube of fan speed.

Thus, speed control not only optimizes fan performance but also leads to significant energy savings, reduced wear and tear, and quieter operation.

Design Considerations for AC Centrifugal Fan Speed Control

Key Factors to Consider When Designing Speed Control Systems

Designing an effective speed control system requires consideration of various factors, including the type of fan, the operating environment, and the desired level of control. Some essential design factors to evaluate include:

• Fan Type and Size: Different centrifugal fans may require different speed control techniques depending on their design specifications.

• Power Requirements: The power needed to drive the fan at various speeds must be understood to ensure the control method is energy efficient.

• System Dynamics: The system's response to speed changes should be stable and predictable to prevent surges or flow instabilities.

Design Parameters Influencing Speed Control Efficiency

Several design parameters significantly impact the efficiency of speed control:

• Voltage and Current Ratings: Ensuring the control components can handle the voltage and current of the fan motor.

• Thermal Management: As speed control may generate heat, ensuring adequate cooling and ventilation is crucial.

• Speed Range and Precision: Determining the necessary range of speed control and how precisely the speed needs to be regulated.

Matching Fan Application Environment with Speed Control Needs

The operating environment greatly influences the choice of speed control method. For example:

• In environments requiring continuous operation, reliable and low-maintenance controls are preferred.

• For applications where noise is a concern, smooth and gradual speed adjustments are necessary to reduce operational noise.

Step-Down Transformer: Efficient Speed Control Using Toroidal Transformers

What is a Toroidal Transformer and How It Works

A toroidal transformer is a type of transformer with a ring-shaped core, offering several benefits over traditional laminated transformers. Its design results in low magnetic flux leakage, reduced electromagnetic interference (EMI), and high efficiency. In the context of AC centrifugal fan speed control, a toroidal transformer can step down the voltage supplied to the fan motor, allowing for a reduction in speed.

Adjusting Fan Speed Through Voltage Reduction

By reducing the voltage supplied to the motor via a step-down transformer, the fan speed decreases proportionally. This method is effective for achieving energy savings because a lower voltage means reduced power consumption. The efficiency of toroidal transformers ensures minimal energy loss during the transformation process.

Advantages of Using Toroidal Transformers

• High Efficiency: Toroidal transformers have better efficiency compared to traditional transformers due to their core design.

• Low EMI: The design minimizes electromagnetic interference, making this method suitable for environments sensitive to EMI.

• Compact and Lightweight: These transformers are smaller in size, making them ideal for applications where space is limited.

Diac and Triac Control: A Method for Precise Speed Regulation

Basics of Diac and Triac Control

Diac and Triac control uses semiconductor devices to regulate AC power and precisely adjust the fan's speed. A Diac is a trigger device that helps control the switching of a Triac, which acts as a bidirectional switch, enabling control over the power supplied to the fan motor.

Steps to Adjust Centrifugal Fan Speed Using Diac and Triac

1. Trigger Signal: A small signal is applied to the Diac, which in turn triggers the Triac to conduct.

2. Phase Angle Control: The conduction angle of the Triac is adjusted to control the amount of AC voltage supplied to the fan.

3. Speed Regulation: The voltage supplied to the motor is modulated, thereby controlling the fan speed.

Energy Savings and Applications for Diac and Triac Control

This method offers precise speed control and energy savings, as the fan speed can be adjusted dynamically according to real-time requirements. It's particularly useful in applications where fine speed control is needed, such as ventilation systems and industrial process fans.

Capacitance Adjustment: Modifying Fan Capacitor for Speed Control

Role of Capacitors in Centrifugal Fan Speed Regulation

Capacitors are commonly used in AC motors to control the phase shift and improve torque. By adjusting the capacitance value, the phase shift between current and voltage can be altered, which influences the fan motor's speed.

Impact of Changing Capacitor Values on Fan Speed and Power Consumption

Changing the capacitance affects the motor's torque characteristics, thereby impacting its speed. Reducing capacitance generally results in a decrease in speed, which can also lower power consumption.

Recommendations for Using Different Capacitor Values for Energy Efficiency

• For Slow Speeds: Use a capacitor with a lower value to reduce the motor's torque and slow down the fan speed.

• For Dynamic Adjustments: Select a capacitor with a range of values to allow variable speed control.

• For Noise Reduction: Adjust capacitance to achieve a smooth and quiet operation.

Comparative Analysis: Pros and Cons of Each Speed Control Method

Advantages and Limitations of Different Speed Control Methods

| Control Method | Advantages | Limitations |

| Step-Down Transformer | High efficiency, low EMI | Limited speed range, bulky components |

| Diac and Triac Control | Precise control, flexible speed range | Requires complex circuitry |

| Capacitance Adjustment | Simple, low cost | Limited speed adjustment, lower efficiency |

Choosing the Right Speed Control Method for Different Applications

• For High Efficiency and Low EMI: Step-down transformers are ideal.

• For Precise Control and Flexibility: Use Diac and Triac-based controls.

• For Cost-Effective Solutions: Capacitance adjustment can be an economical choice.

Practical Tips for Implementing Speed Control Solutions in AC Centrifugal Fans

Effective Application of Speed Control Techniques

• Ensure Compatibility: Match the speed control method with the fan's electrical specifications.

• Use Feedback Loops: Implement feedback systems for dynamic adjustments to maintain optimal performance.

• Test Performance: Before full-scale implementation, test the system to ensure stability and efficiency.

Routine Maintenance and Checks for Optimal Performance

• Inspect Connections Regularly: Ensure all electrical connections are secure and free of corrosion.

• Monitor Temperature: Check for overheating in the motor or control components.

• Clean the Fan Blades: Keep the fan blades clean to maintain efficiency and reduce power draw.

Conclusion: Maximizing Energy Savings Through Effective Speed Adjustment

Effectively controlling the speed of AC centrifugal fans offers multiple benefits, including reduced energy consumption, optimized performance, and prolonged equipment life. By selecting the appropriate method for speed control, such as step-down transformers, Diac and Triac control, or capacitance adjustments, engineers can maximize energy savings and enhance the efficiency of their systems. Proper design considerations and maintenance are essential for achieving the best results and ensuring the longevity of both the fan and the control system.

By implementing these best practices, product development engineers can ensure that AC centrifugal fans operate efficiently, helping to reduce energy costs while maintaining performance.

.png)

.jpg)

.jpg)

_top.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)