PRODUCTS

SEARCH PRODUCT

AC Centrifugal Fans

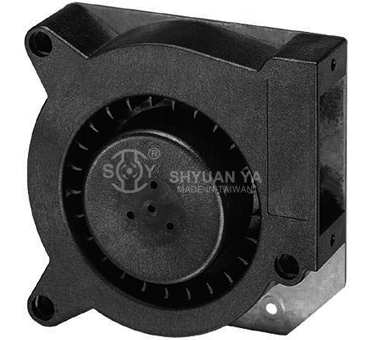

BA12C37T / Portable Exhaust Fan

| Air Flow | 22 ~ 23 CFM |

|---|---|

| Static Pressure | 0.42 ~ 0.62 inch-H2O |

| Noise | 53 ~ 54 dB(A) |

| Bearing | Ball or Sleeve |

| Safety | Impedance Protected |

| Weight | 625g |

Why Choose Us

Thermally Protection with Better Insulation

One body injected insulation case provides better insulation between coil and silicon steel. Thermal protector prevents motor overheating.

Electricity Saving

The conversion efficiency of our fans is generally about 10% higher than other manufacturers by applying Advanced Geometry design.

Longer products lifetime

The winding of our fan motors is 100% made by copper. Using good quality wire bring longer life expectancy to all series of fans.

Stronger Impeller Structure

One body injected impeller has stronger structure and better balance compared with impeller mounted with a metal plate.Product Video

Specification

- Item Code

- BA12C37T

- Housing

- Spiral Housing of Fiberglass-Reinforced Polycarbonate Housing Base of Galvanized Steel Plate

- Impeller

- Thermoplastic PBT, UL94V-0

- Motor

- Shaded-Pole Motor

- Termination

- Lead Wire

- Voltage Range

- 85VAC to 125VAC for 115V Type

185VAC to 245VAC for 230V Type

- Insulation

- Class “B” or “F”

- Operating Temperature

- -10℃ to +70℃ for Sleeve Type

-20℃ to +80℃ for Ball Type

| Item Code: BA1V12C37TBL-2 | |||||||||

|

Rated Voltage |

Frequency (Hz) |

Rated Current(A) |

Input Power(W) |

Speed (RPM) |

Air Flow (CFM) |

Air Flow (m3/min) |

Static Pressure (inch-H2O) |

Noise dB(A) |

Capacitor (uF) |

|---|---|---|---|---|---|---|---|---|---|

| 115V | 50/60 | 0.27/0.24 | 21/19 | 2500/2500 | 22/23 | 0.62/0.65 | 0.42/0.62 | 53/54 | NONE |

| Item Code: BA2V12C37TBL-2 | |||||||||

|

Rated Voltage |

Frequency (Hz) |

Rated Current(A) |

Input Power(W) |

Speed (RPM) |

Air Flow (CFM) |

Air Flow (m3/min) |

Static Pressure (inch-H2O) |

Noise dB(A) |

Capacitor (uF) |

| 230V | 50/60 | 0.14/0.12 | 21/20 | 2500/2500 | 22/23 | 0.62/0.65 | 0.42/0.62 | 53/54 | NONE |

Outline Drawing

.png)

Charateristic Curve

Related Products

Manufacturing Process

Step 1. Motor Winding

Winding coils to fan motors

Step 2. Motor Testing

Testing ohm value of coils.

Step 3. Motor Connection

Connecting lead wires to fan motors

Step 4. Hi-POT & Impulse Testing

Testing insulation between coils and bottom cases

Step 5. Motor Mounting

Mounting fan motors to bottom cases

Step 6. Dynamic Balancing

Balancing impellers

Step 7. Impeller Assembling

Assembling impellers to fan motor

Step 8. Pre-Delivery Inspection

Testing vibration、current、wattage of fans

Step 9. Pre-Delivery Hi-POT Testing

Testing insulation between fan motors and bottom cases.

Step 10. Packing

Company Overview

Professional & Customized Service

SHYUAN YA Group was founded in 1982 with more than 40 years’ experience in fan industry. Our professional teams in molding and R&D departments can provide technical suggestions and customized services to our customers.

Besides,up to 85% of fan components including fan motors are made in our factories which located in Taiwan.

Besides,up to 85% of fan components including fan motors are made in our factories which located in Taiwan.

1982

Set Up

40 years experience

Manufacturing experience

Up to 85%

Self-Manufacturing

Inspection Equipments

Quality Stability & Reliability

To ensure that high standard and reliable products are delivered to our customers,100% products inspections are conducted at the end of production line. Our main inspection equipment includes Semi-Anechoic Room which is one of the biggest sizes in the fan industry and background noise down to 10.0 dBA.

The air flow chamber that can be used for measuring air flow for any kind of fan. and measurement range up to 1,300 CFM.

The air flow chamber that can be used for measuring air flow for any kind of fan. and measurement range up to 1,300 CFM.

100% products inspections

High standard

Down to 10.0 dBA

Background noise

Up to 1,300 CFM

Measurement range

Production Equipments

Short Production Time & Prompt Delivery

SHYUAN YA Group has invested over two million US dollars on upgrading production facilities & inspection equipment. Our production lines include plastic injection, motor winding, and die casting processing lines.

Most importantly, maximum 16 Assembling lines can shorten production time which normally takes about 4~6 weeks.

Most importantly, maximum 16 Assembling lines can shorten production time which normally takes about 4~6 weeks.

Over two million US dollars

Investment funds

16 lines

Assembling lines

4~6 weeks

Mass Production

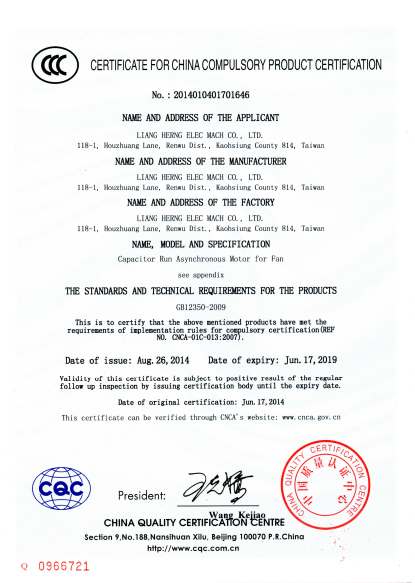

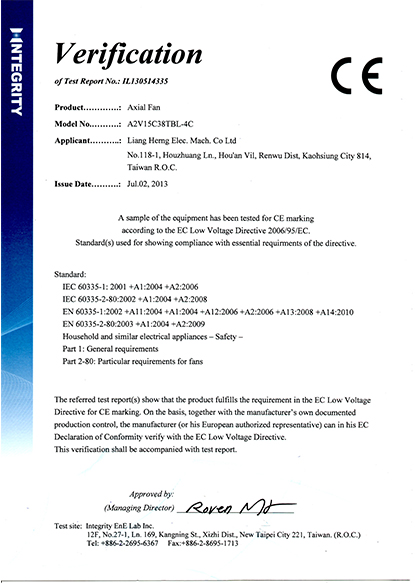

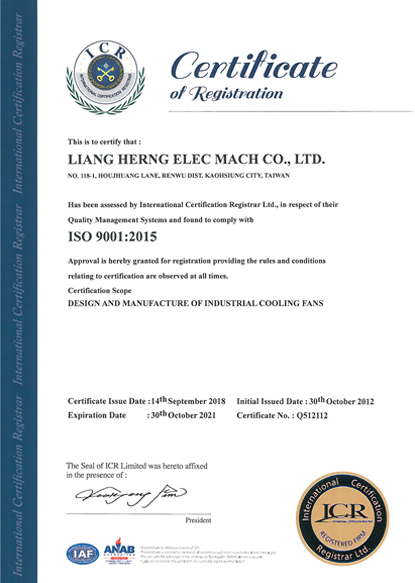

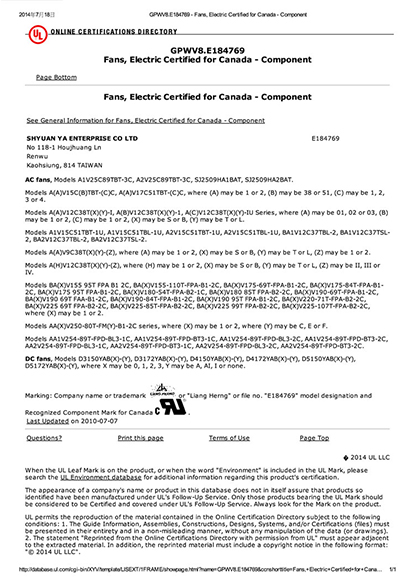

Certification

Certification

- ShyuanYa have met the worldwide standards and have qualified by ISO 9001:2015 and CQC quality system.

- All our products are approved by UL (E184769)/ CUL/ CE , as well as in compliance with RoHS requirement.

- CCC Certification

- CE Certification

- ISO 9001 2015 Certification

- UL Certification

Packing & Delivery

STEP 1

Packing Products

STEP 2

Packing Products

STEP 3

Loading Area

STEP 4

Stuffing

STEP 5

Stuffing

STEP 6

Stuffing

Trade Shows

- MCE

- Build4Asia

- HVACR ASIA

- KE SHOW

- TAITRONICS

Video

Related FAQ

Portable Exhaust Fan:

SHYUAN YA has over 40 years experiences of producing Portable Exhaust Fan with a Portable Exhaust Fan factory in Taiwan. We own experienced artisans in order to deliveries top quality Portable Exhaust Fan to our customers. Our Portable Exhaust Fan provide longer

lifetime the fan motors is 100% made by copper, using good quality wire bring Portable Exhaust Fan longer life expectancy to all series of fans. Welcome contact us Portable Exhaust Fan, Portable Exhaust Fan Supplier, Portable Exhaust Fan Manufacturer.

Portable Exhaust Fan Specification:

Portable Exhaust Fan Air Flow: 22 ~ 23 CFM

Portable Exhaust Fan Noise: 53 ~ 54 dB(A)

Portable Exhaust Fan Bearing: Ball or Sleeve

.png)

.jpg)

.png)

_top.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)