The Critical Role of Centrifugal Fans in HVAC Systems: A Guide for Procurement Teams

The Critical Role of Centrifugal Fans in HVAC Systems: A Guide for Procurement Teams

Centrifugal fans are a vital component in modern HVAC (Heating, Ventilation, and Air Conditioning) systems, ensuring effective air circulation, temperature regulation, and ventilation across a variety of commercial and industrial settings. For procurement teams, selecting the right type of centrifugal fan is crucial for maximizing energy efficiency, reducing noise, and meeting system requirements. This guide explores the critical role these fans play in HVAC systems, their benefits, and how to evaluate them for optimal performance.

Understanding the Basics: What is a Centrifugal Fan?

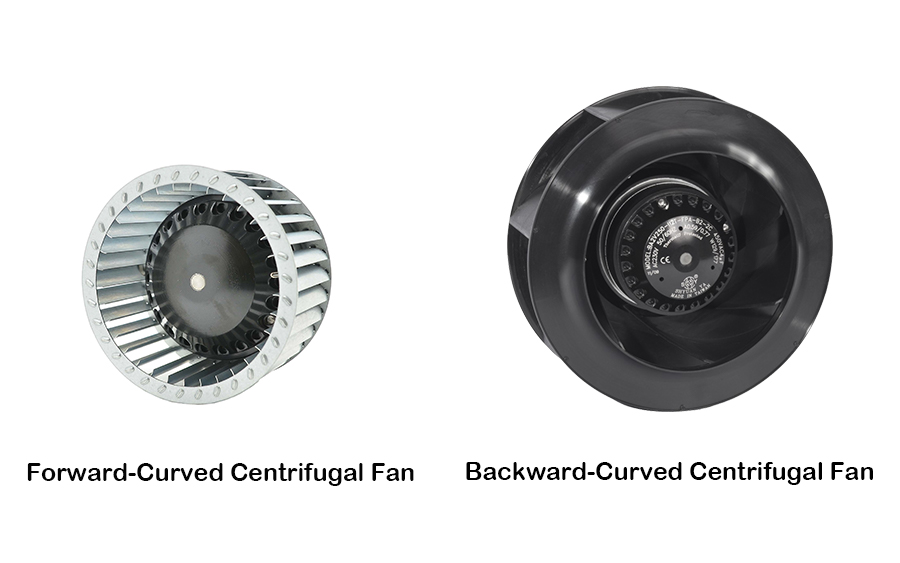

A centrifugal fan is a type of mechanical device that moves air or other gases in a specific direction using a rotating impeller. Unlike axial fans that push air along the axis of rotation, centrifugal fans draw air into the center of the fan and push it outward through a 90-degree angle. This design allows for higher pressure generation, making centrifugal fans ideal for applications requiring significant airflow at a higher pressure, such as in HVAC systems. The impellers in centrifugal fans can be designed in various forms, including forward-curved, backward-curved, and radial configurations, each offering distinct advantages depending on the application.

Why Centrifugal Fans are Essential for HVAC Systems

Centrifugal fans play a vital role in HVAC (Heating, Ventilation, and Air Conditioning) systems due to their efficiency and ability to handle varying air volumes at different pressure levels. In an HVAC system, the fan is responsible for circulating air throughout the space, ensuring proper ventilation, temperature control, and air quality. The ability of centrifugal fans to generate higher static pressure compared to axial fans makes them particularly suitable for HVAC applications, where air needs to be moved through complex ductwork and across filters or heat exchangers. Additionally, the flexibility in fan design allows HVAC engineers to select the most appropriate fan type—forward-curved for quieter operation and lower speed applications or backward-curved for higher efficiency and lower maintenance needs.

Key Benefits of Using Centrifugal Fans in Commercial HVAC Applications

The use of centrifugal fans in commercial HVAC systems offers several significant benefits:

- Energy Efficiency: Centrifugal fans, particularly those with backward-curved impellers, are highly efficient in converting mechanical energy into airflow, reducing energy consumption and operational costs.

- Noise Reduction: Forward-curved centrifugal fans operate at lower speeds, producing less noise, which is crucial in commercial environments where a quiet atmosphere is essential.

- Durability and Low Maintenance: The robust construction of centrifugal fans, especially those with backward-curved blades, ensures long-term durability and minimal maintenance, making them ideal for continuous operation in demanding environments.

- Versatility: Centrifugal fans can be adapted to various HVAC needs, from high-pressure requirements in industrial settings to more delicate air handling in office buildings and hospitals.

How to Evaluate Centrifugal Fans for Your HVAC System Needs

When selecting a centrifugal fan for your HVAC system, consider the following factors:

- Airflow Requirements: Determine the required airflow volume (CFM) and static pressure needs of your system. Choose a fan that can meet these demands efficiently.

- Noise Levels: Assess the acceptable noise level for the environment in which the fan will operate. Forward-curved fans are typically quieter, making them suitable for noise-sensitive areas.

- Energy Efficiency: Look for fans with higher efficiency ratings to reduce energy consumption and operational costs over the lifespan of the system.

- Size and Space Constraints: Ensure the fan’s size and installation space are compatible with the existing HVAC system layout.

- Maintenance Needs: Consider the maintenance requirements of the fan. Backward-curved fans often require less frequent maintenance, making them ideal for systems that need to run continuously with minimal downtime.

Common Challenges and Solutions When Integrating Centrifugal Fans

Integrating centrifugal fans into HVAC systems can present several challenges:

- Ductwork Compatibility: Ensuring that the fan’s output aligns with the ductwork design is crucial for optimal performance. Incorrect sizing can lead to inefficiencies or increased noise.

- Pressure Drops: Significant pressure drops across filters or heat exchangers can impact fan performance. Choosing a fan with sufficient static pressure capacity can mitigate this issue.

- Noise Control: In environments where noise control is critical, selecting the appropriate fan type and incorporating sound-dampening measures can reduce operational noise levels.

- Energy Consumption: Balancing airflow needs with energy efficiency requires careful fan selection and potentially the integration of variable frequency drives (VFDs) to optimize fan speed and energy use.

Case Studies: Successful Implementation of Centrifugal Fans in HVAC Systems

- Office Buildings: A large corporate office required a quiet yet efficient HVAC system. By selecting forward-curved centrifugal fans, the building management achieved the necessary airflow while maintaining a quiet work environment. The fans’ low-speed operation minimized noise, contributing to a comfortable office setting.

- Industrial Facilities: An industrial plant needed to circulate air through a complex system of ducts with high static pressure requirements. Backward-curved centrifugal fans were chosen for their efficiency and durability, ensuring consistent airflow and reducing the frequency of maintenance, even in the demanding industrial environment.

Future Trends in Centrifugal Fan Technology for HVAC Systems

The future of centrifugal fan technology in HVAC systems is likely to focus on:

- Energy Efficiency Improvements: Ongoing advancements in fan design, such as optimized blade shapes and materials, are expected to enhance efficiency, further reducing energy consumption.

- Smart Integration: The integration of smart controls and sensors will allow for more precise control of fan operation, leading to better energy management and system performance.

- Noise Reduction Technologies: Continued innovation in noise reduction technologies will make centrifugal fans even more suitable for environments where quiet operation is critical.

- Sustainable Materials: The use of sustainable and recyclable materials in fan construction is likely to increase, aligning with broader environmental goals and reducing the carbon footprint of HVAC systems.

Centrifugal fans remain a cornerstone in HVAC systems, providing reliable and efficient airflow to meet diverse needs in both commercial and industrial environments. Understanding their different types, benefits, and challenges enables procurement teams to make informed decisions that enhance system performance and sustainability. As technology advances, trends like energy-efficient designs, smart controls, and improved noise reduction will continue to shape the future of centrifugal fans, ensuring they remain essential in HVAC applications for years to come.

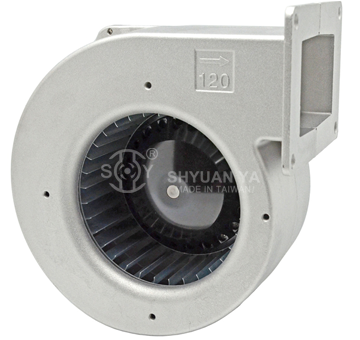

Related Product:

| DC Centrifugal Fans | AC Centrifugal Fans | Centrifugal Blowers |

|

|

|

.png)

.jpg)

.jpg)

_top.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)